Process Development & Improvement / CNC Training

Great things happen when you work SMARTER and HARDER.

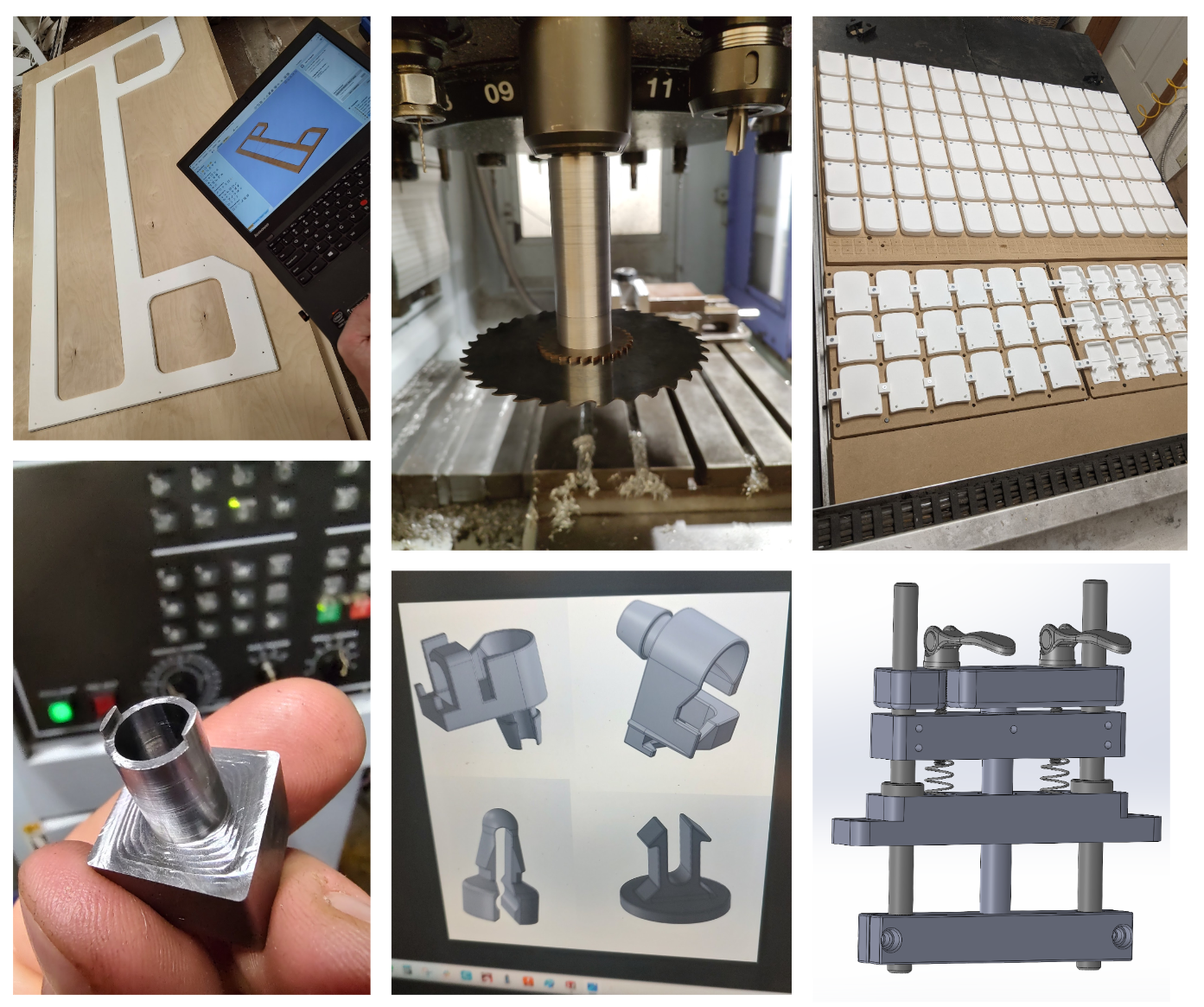

We help our clients run faster, more parts per cycle, and with less scrap, OR get setup from the ground up.

Whether you struggle with tooling selection, programming challenging features, long cycle times, inconsistent workholding, or designing for manufacturability - we can help you!

Take full advantage of your existing equipment by using the advanced features you may not know exist.

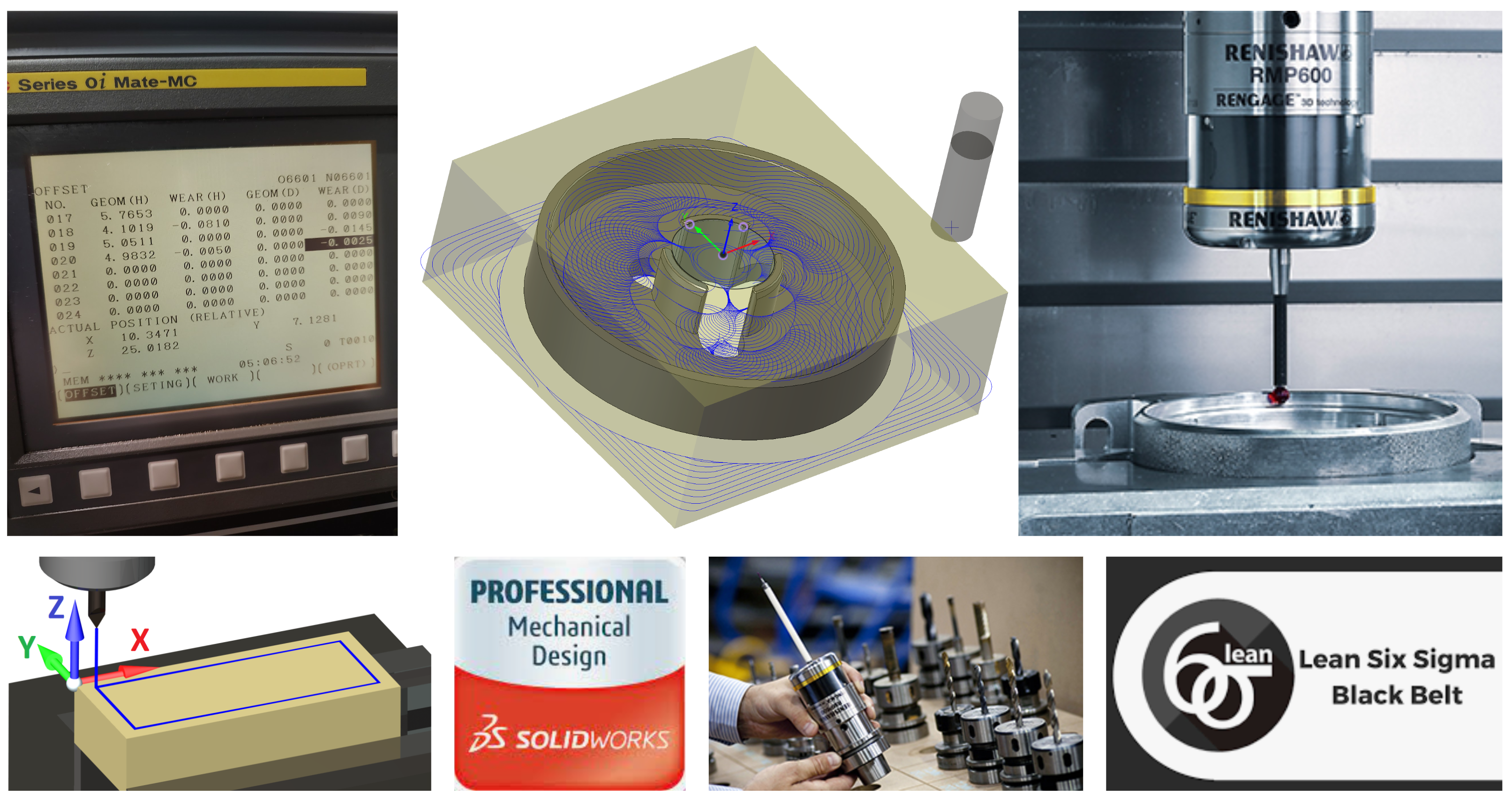

How do you handle work offsets and tool length / diameter / wear compensation? Have you implemented high speed machining techniques? Do you use vices, subplates, or any sort of palletized systems? Do you use macro programming?

Need to scale up production on existing machines? Or bringing new CNC equipment in-house?

We will work with your team to set-up or ramp-up production with efficient operations, tooling, programming, and fixturing for a smooth transition into production operations.

Does your machining center have a touch probe or toolsetter, but not sure how to use it??

Probes can do more than just set work offsets. You can automatically adjust for tool wear, add in-process inspection or collect SPC data, and “poka-yoke” your loading and fixturing process to eliminate scraps from human error. Our knowledge and experience with Renishaw touchprobes can help you control and elevate your machining processes.

Interested in a group training for your team?

Contact us to discuss your project or training needs.

We can work remotely or on-site at your facility.

Daily, weekly and retainer rates are available.

Expedited services available.